Atomic Films Laboratory

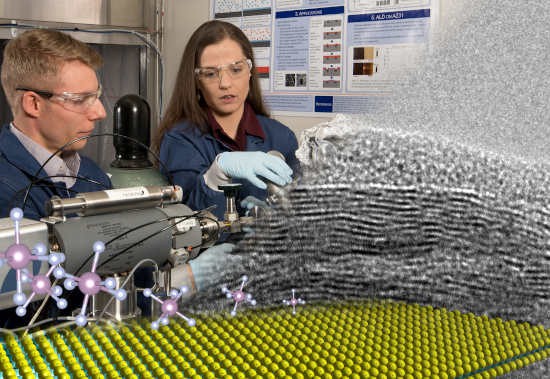

The Atomic Films Lab works to develop thin film deposition and characterization processes and to apply thin film coatings to a range of applications. A key area of our research is the development of atomic layer deposition (ALD) processes for atomically-thin two-dimensional (2D) materials, which may be only a few atoms in thickness.

Our interests lie in developing new ALD processes for materials with potentially useful properties. Often, it is necessary to understand the chemical reactions at a fundamental level in order to establish a reliable ALD process. To gain this fundamental understanding, we develop and employ a range of characterization tools. Some of our tools are listed below, and you can learn more at the ALD and SPM pages. We also collaborate with many other groups who provide complementary capabilities and expertise.

People are the most important part of what we do. We are fortunate to have a group of outstanding students, faculty, staff, collaborators, and mentors, all with diverse perspectives and unique experiences. We challenge and support each other in an open, collaborative, respectful, and fun group culture in which we all value the pursuit of knowledge.

Facilities

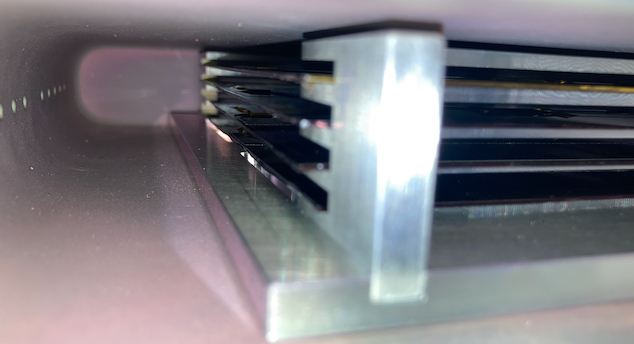

See the ALD and SPM pages for further details and information.- Custom tube furnace based ALD system

- Arradiance GEMStarXT ALD system (open access)

- Omicron/RHK UHV STM

- Hitachi TM-1000 benchtop SEM (under repair)

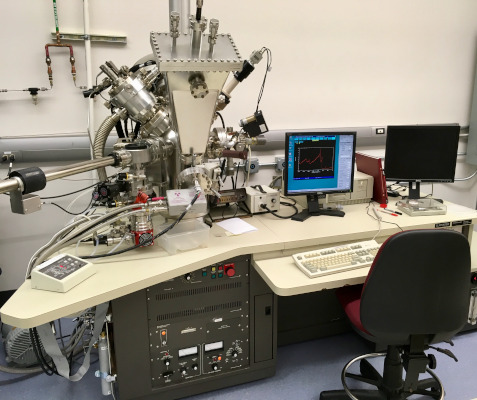

- PHI 5600 ESCA X-ray photoelectron spectroscopy (XPS) system (open access)

- Sputter depth profiling with Ar, Ne, or Xe

- Sealed sample transfer vessel (e.g., glovebox to XPS load-lock)

- Samples up to ~100 mm in diameter

- Nicolet Magna 550 FTIR (open access)

- Inficon Transpector MPH Compact Process Monitor (open access)

- 200 amu quadrupole mass spectrometer

- Process bypass line

- Selectable inlet orifice

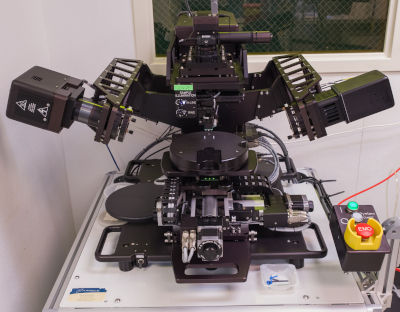

- J.A. Woollam M-2000 Spectroscopic Ellipsometer (open access)

- 245-1690 nm, 660 wavelengths

- Auto tip-tilt 100 mm x 100 mm scanning stage

- Focusing optics (120 micron spot)

- Access and training managed by the Idaho Microfabrication Lab

|

|

|

|

|

|

|

|

Please feel free to contact me.